Electric vehicles (EVs) are currently perceived as a promising alternative to replace fossil fuelled transport, in the pathway to reduce carbon emissions. There has been also some controversy of its potentiality, due to concerns about their batteries in terms of costs, efficiency and life-cycle. As a researcher working in projects integrating electric vehicles and energy storage, I’m frequently asked about how clean and efficient are EVs if they depend on batteries? I attended the Battery Masterclass event organised by Cenex and LEVEL, the talks from different experts in the field summarised the value and challenges that EVs are facing now to be able to decarbonise the transport system. Therefore, I will try to summarise some of the Frequently Asked Questions to understand the status quo of EVs’ batteries.

What are the current challenges associated with the mass production of batteries for EVs?

Lithium-ion batteries surpassed other technologies for automotive application in the path to replace internal combustion engines. Currently, it is possible to say that this energy storage solution is the front-runner when compared to other technologies such as Solid State or Li-air, due to its readiness, emissions, recyclability and efficiency. However, it is still under active development and it is expected that it will have improvements in terms of costs, energy density, power density, safety, first life, temperature, predictability and recyclability in the coming decades.

Dr Anna Wise from Innovate UK summarised the technical targets expected to be met by the battery industry by 2035:

- Reduction of the costs of batteries over 60%

- Double the energy density from 700Wh/l, 250Wh/kg (cell) to 1400Wh/l, 500Wh/kg (cell)

- Increase the power density from 3 kW/kg (pack) to 12 kW/kg (pack)

- Eliminate thermal runaway to improve safety

- Extend the battery first life up to 15 years (currently 8 years)

- Increase the temperature range to +/- 20°C (currently -20°C to + 60°C)

- Have available full prediction models to assess performance and ageing of the batteries

- Recycle up to 95% of the battery pack (currently 10 to 50%)

Batteries are fabricated using rare minerals, so what are the strategies to minimise the environmental and social impacts?

The down side of Lithium-ion batteries is the need to mine rare minerals such as Lithium which comes mainly from South America, Cobalt extracted mainly in DRC and Zambia; and Nickel mined in Australia, Canada, Russia, Indonesia and the Philippines. David Philipson from Cenex explained that this mining process has environmental, humanitarian and political impacts.

It has been reported that the mining process of Cobalt and Nickel can contribute highly to global warming. The life-cycle analysis of these minerals suggest that this is due to the amount of electricity required for the mining process. Therefore, the integration of renewable energy is required in the mining industry and the energy grid to be able to minimise the carbon emissions during the production of batteries.

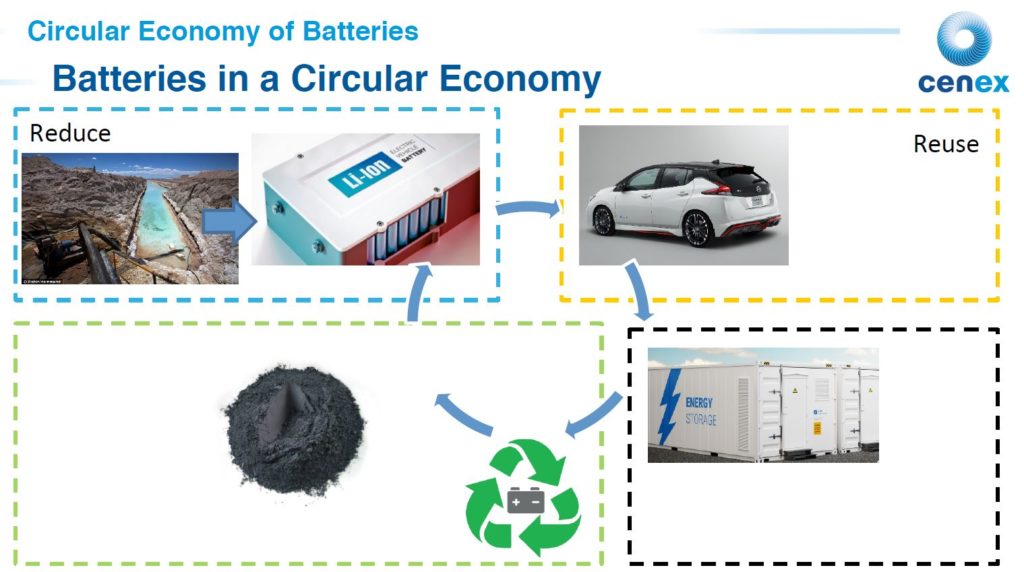

Moreover, the batteries will need to be part of a circular economy to allow: reducing the demand of rare materials, stabilising the market, and minimising the amount of residual waste. Samuel Abbott from Cenex explained that the circular economy is achieved by:

i) Reducing the amount of materials required

ii) Reusing the batteries for second life applications

iii) Recycling the different compounds of the battery

EV batteries are at the end of its useful life when they reach 70-80% of the energy capacity. However, they can be used up to 50% of its degradation for other energy storage purposes . There are successful cases of using second life EV batteries to store renewable energy. As an example, Nigel Dent from Connected Energy presented a project located in Dundee, Scotland. Connected Energy developed EV Charging Hubs integrating: i) a canopy with solar PV panels, ii) second life batteries for energy storage, and iii) EV chargers. This system works by generating electricity from the sun, storing the energy in the second life batteries and charging the vehicles with renewable energy, any surplus generated is sent to the grid. The environmental benefits of this development are enormous, as:

- It reduces the CO2 kilograms per kWh of the battery by extending its use.

- The batteries are used to store renewable energy to charge electric vehicles, helping to decarbonise the transport system.

- The Charging Hubs allow to control the energy demand of the grid coming from the transport sector.

According to Samuel Abbott, the following step in the circular economy of the battery is to recycle its components to minimise the need of new raw materials. Batteries not only have a complex supply chain, but also a complex composition. A 40 kWh battery pack has around £800 worth of precious metals. There are current commercial examples of eco-friendly battery recycling business. For instance, the process implemented by Duesenfeld can achieve to recycle up to 85% of the material of a Lithium-ion battery system. It is estimated that this process can reduce Lithium-ion battery’s carbon footprint up to 40%.

And what about the battery degradation?

The current battery’ first life is eight years. As part of the technical targets, it is expected to increase this up to 15 years. According to Dr Anup Barai from the University of Warwick, the battery degradation depends on the use of the vehicle. The variables considered when testing battery degradation are: charge-discharge rate, temperature, depth of discharge and average state of charge. Dr Barai explained that some of the factors accelerating the degradation of batteries are: high discharge current, high temperature, low temperature and change in pressure. Due to the multiple variables affecting the battery degradation there is not battery that fits all the purposes, therefore it is required to think in the application of the vehicle, duty cycle, temperatures, and how they are going to degrade the battery at the end. In this field there is a high opportunity to integrate behavioural analysis of vehicles where the patterns of charging and discharging can contribute to estimate the battery degradation.

Final thoughts…

To summarise, it is important to recognise that EV batteries are complex elements due to their production chain, applications and recyclability. This complexity offers numerous business opportunities that could contribute to reduce carbon emissions and global warming. Around 50% of the CO2 emissions of the battery are generated in the manufacturing process (Hall and Lutsey, 2018). Therefore, by decarbonising the energy grid, we will be decarbonising even more the transport sector, “Decarbonisation of electric grids around the world by an average of about 30% will result in approximately 17% lower battery manufacturing emissions by 2030” (Hall and Lutsey, 2018, p. 7).

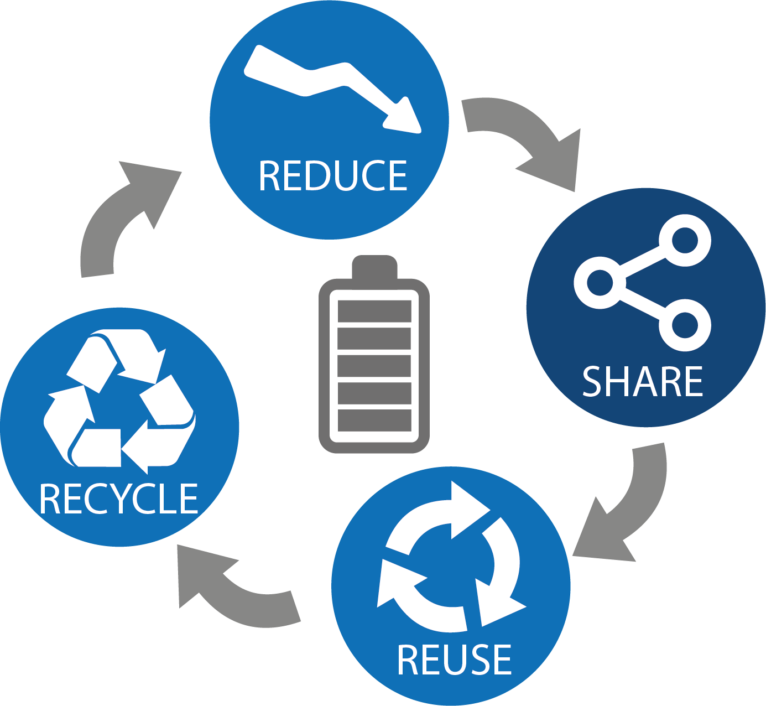

Electric vehicles can support the storage of renewable energy by using vehicle-to-grid (V2G). In this way EVs are not only passive consumers of the energy grid, but contribute to the transition to clean energy. So, I consider that the circular economy of the battery can also include the capacity of EVs to share energy . In this way the circular economy of the battery would be:

i) Reducing the minerals required to produce new batteries

ii) Sharing renewable energy stored to maximise the the 1st life cycle and support the grid system

iii) Reusing the batteries in 2nd life applications

iv) Recycling the components of the battery

It was a great event organised by Cenex and LEVEL. We will be attending the next event “Electric Vehicle Charging Innovations Conference” on the 4th of December 2019. If you are planning to attend, please come and have a talk with our team at the stand of EV-elocity.

Blog by Dr Julie Waldron, Research Fellow from the Buildings, Energy and Environment Research Group, University of Nottingham